Centrifugal Gas Separators

Ryobran “RCGS” Centrifugal Gas Separators will separate and release air and gas from petroleum and other liquid products (with a dynamic viscosity <20Cp) before they are metered. The centrifugal gas separator is a necessary part of any liquid flow metering installations using pumps as the motive force.

Purpose

The separation and removal of air or gas from a liquid is controlled and limited by the physical properties of that liquid and influenced by a combination of temperature, pressure, flow rate, and system design.

The presence of gas or air in a liquid system while being measures by a turbine meter or positive displacement, will result in obtaining an inaccurate measurement and can also cause damage to the meter.

Principle of Operation

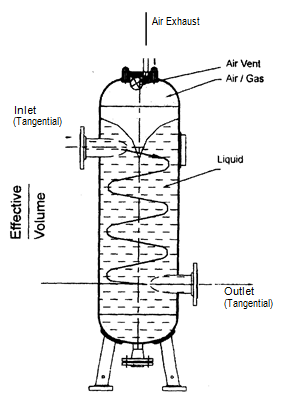

The fluid enters the gas separator through the tangentially constructed inlet nozzle. This causes a rotational flow along the inside wall of the vessel. This rotational flow is maintained by the tangentially constructed lower outlet flow nozzle. The centrifugal movement of the fluid in conjunction with a decrease in flow velocity and pressure forces the heavier parts (fluid) to the inner wall of the vessel where the lighter parts (air/ gas) collect at the center and rise to the top where they are released through an automatic float operated air vent (AV1000 /AV 1500).

Installation and Operation

The air I gas separator should be installed at the closest possible distance upstream of the meter in order to separate air or gas from the liquid. Consideration must be given to the system design to assure sufficient back pressure (min. 7.5 psig). The air I gas separator is recommended to be installed between the strainer ar.id the meter. In case the air I gas separator is installed upstream of the strainer it must be thoroughly cleaned before final start-up. After start-up, the separator must be drained of accumulated mud at regular intervals. The drain pipe is provided for this purpose at the bottom of the separator. The air I gas release should be piped to a safe point of discharge (flame arrester). The condensate return can be discharged into a suitable container or back to storage.

Why Choose Us?

Quality Assurance

All our products are manufactured using top notch material and pass all quality tests

Competitive Pricing

Our products are priced competitively so you don’t have to look anywhere else

Client Satisfaction

We believe that providing 100% Client Satisfaction will lead to Client Loyalty

After Sales Support

We provide support to our clients even after we deliver

Innovation

We innovate so that your customized requirements are fulfilled

Experience

19+ years of Manufacturing experience making products that last